QUALITY MANUAL -> 8.1.2 CONFIGURATION MANAGEMENT

Configuration is a documented information covers the technical and physical specifications of the product. This documented specs are open for the distributors and customers, to avoid any fault or mis-ordering process.

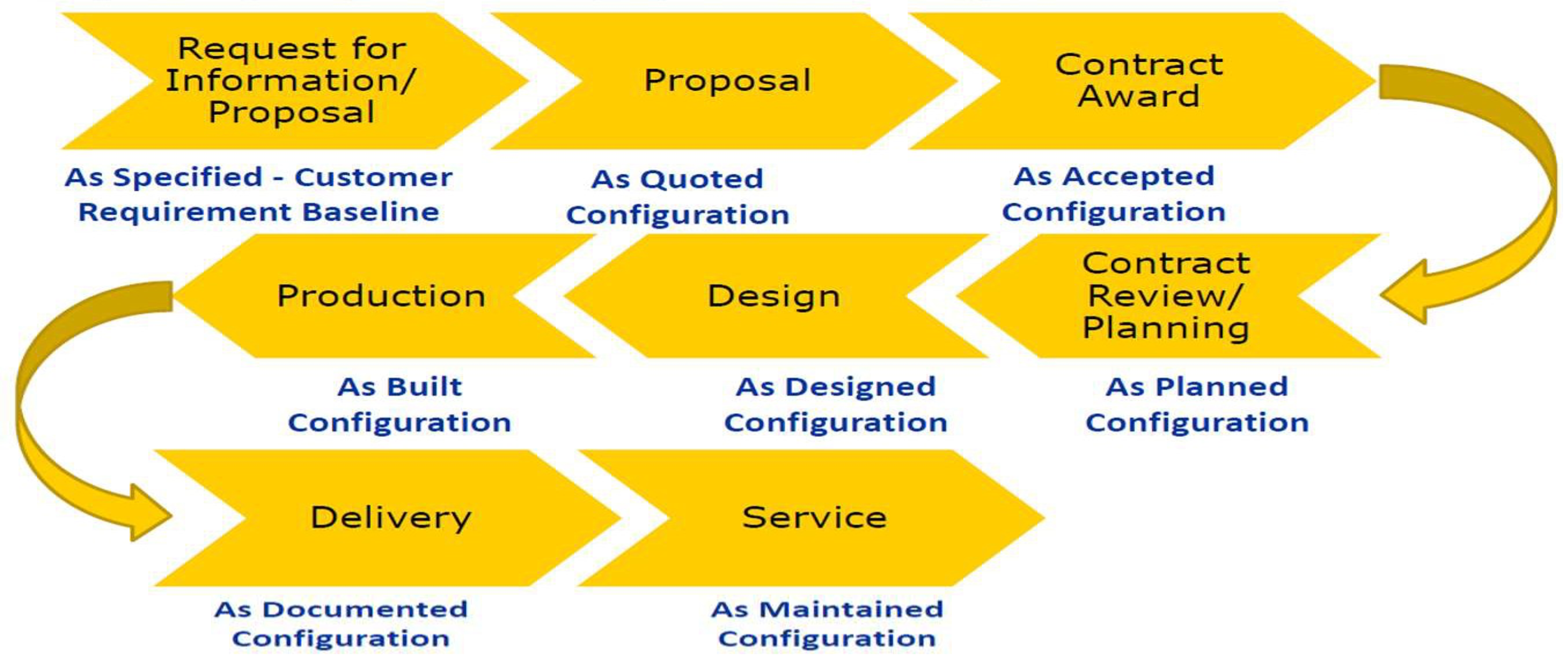

Configuration Management is a discipline to keep, manage and reports the records, technical and physical revisions for a product in its lifecycle.

According to Loran quality management policy, the configuration management is a supplying discipline covers the phases from production to the distributors operations. For this discipline to be implemented safely, procurement specifications must include the following explanations:

- Internal control stages of the processes and procedures,

- Customer purchase order identification of products to be shipped,

- Manufacturer’s identification of products supplied,

- Documentation associated with quality control and test reports,

- Product status including revision level, shelf life and life cycle information.

Loran carries out configuration management according to the ISO 10007:2017 (3rd Edition) Quality management — Guidelines for Configuration Management Standard. At the same time, Loran also implements the following technical guidelines when determining its configuration policy:

- "Piece Parts" Requirements are clarified in the SAE technical report of the "CMB5 Configuration Management Requirements for Subcontractors/Vendors Rev.A 2014" of when determining its configuration policy.

- SCMH 7.5.3 Configuration Management Guidelines (Rev. B 2021)

In Loran configuration management, all approval negotiations between customer requirements and supplier specifications are carried out by Loran top management. Loran's main target is to prevent any problems between customer demands and the manufacturer's product arising from the following:

- Traceability and documented information requirements,

- Production revision number,

- Alternate Raw material and standards,

- Acceptance conditions and classification of test reports,

- Delivery lead time,

- Product quality and revision of the product,

Revision and Configuration Information:

Unless specified in the manufacturer's technical documentation or unless specifically stated in the customer requirements, Loran's supply responsibility is to supply the latest version of the product is manufactured by the manufacturer, depending on the product descriptive reference information. Loran is not responsible for stating the revision number or configuration status of the product in the quotation. Product revision and configuration information is a matter under the responsibility of the customer, which must be specified by the customer in their purchase order. Loran also states this requirement in the Terms of Conditions of Quotation and Order Acknowledgement.

Recording the Configuration Requirements:

If there are special requirements regarding the product requested by the customer or if there are configurations applied to the product by the manufacturer, Loran records this information in the Properties Special - Configuration Requirements section during product registration in the ERP system.

To avoid any problems related to the configuration or revision level of the product, Loran clearly states all information about the offered products in its quotations.

If Loran knows the revision or configuration status regarding the production condition of the product, it also states this in the quotation text. If the quotation is accepted by the customer, the product is supplied depending on this revision / configuration.

IMPORTANT

Since Loran is not a manufacturer or authorized distributor, it is not obliged to decide on the configuration status of a product or recommend it to its customer or keep a configuration diagram for the product based on its technical ability, competence and authorization.